|

-

»

Channels

» Profiles, Mouldings, Special Shapes & Sections

- Angles, Angle Irons,

L-Shapes & V-Shapes

-

»

Specialty Tubing

-

»

Rings, Rims, Clamps, Flanges, Hoops & Bezels

- Holders, Mountings, Edgings, Trim, & Retainers

- Railings & Brackets

- Z-Bars, Purlins

-

»

Frames & Framing, Diffusers, Grills & Baffels

- Panels, Fins & Plates

-

»

Tracks, Ducts, Rails & Slides

- Stainless Steel Track Caps & Covers

- Caps, Covers, Cladding & Flashings

- Hinging: Louvers, Blades, Slats, Panels, & Beads

- Slats, Strips, Gaskets, Battens & Curved Tape

-

»

Bars & Sections: T, H, W & Double Channels

-

»

Wire Products: Strips, Straps & Rings

-

»

Other Products

- These Profiles Can Be Made Into:

- Shelf Support Tubing

- Barricade Legs and Supports

- Type 1 Barricade Legs and Parts

- Type 2 Barricade Legs and Parts

- Type 3 Barricade Stands

- Shade Rollers

- Hem Bar, Bottom Bar & Hem-Line Channels

- Price Card Mouldings

- Towel Bars

- Curtain Rods

- Shower Rods

- Closet Rods, & Wardrobe Bars

- Drawer Slides

- Drip Edges, Caps & Flashing

- Fence Rails, Posts, Pickets & Stiffeners

- Din Rails, Bus Bars Wireways, Cable Trays, & Bus Ducts

- Heat Transfer Plates

- Scuff Plates, Roof Bows, & Hat Posts

- PVC Rail, Frame, Tubing & Pipe Stiffeners and Reinforcements

- Sink Mouldings, Grip Rims, & Prong Strips

- Security Storm Door Frames

- Stampings

- R.V. & Car Luggage Rack Tubing

- Mirror Frames

- Reflector Panels

- Snap-On Mouldings

- Storm Window & Screen Frames

- Handles

- Siding Trim

- Roll Up Slats

- Wall Studs & Partition Framing

- Sink Legs

- Industries Served

-

»

Resources & Links

- See Online Catalog

- Gwenco Mfg

- Oak Rite Mfg. Corp.

|

|

|

|

|

|

|

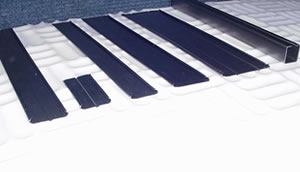

Work Samples

* All Products are produced to order. No Stock Products.

Check out this SME youtube video of Roll Forming

Johnson Bros. has produced this very complex part (seen above) by doing all inline fabricating in the "Cutoff Operation". This inline fabricating includes the countersinking of holes in the cutoff. Thus, "Roll Forming" and "Stamping" operations are combined in the forming of this part. This part is made for a customized racking system for a customer who supplies fixtures for the retail store industry.

It is produced in .120" thick steel and becomes plated after forming. Tolerances from slot to slot are =/-.005" so that slots are in alignment with each other as they are mounted as a racking system. Having accomplished all press fabricating completely in the cutoff die allows closer tolerances to be held than would be given using prepunch tooling due to material stretch in the Roll Forming operations roll dies. The latest in die accelerator technology used in the Cutoff operation is a must to produce this complex "Roll Formed" part.

|

| Applicable Categories |

| Profiles,

Mouldings, Special Shapes |

| Lock

Seam |

| Holders,

Mountings, Edgings, Trim,

Retainers |

| Framing |

| Slats,

Strips, Gaskets, Battens |

| Panels,

Fins, Plates |

| Caps,

Covers, Cladding, Flashings |

| Railings

& Brackets |

| Accompaniments |

| Price

Card Mouldings |

| Misc.

Channels |

| |

|

Applicable Categories |

| Price

Card Mouldings |

| Profiles,

Mouldings, Special Shapes |

| Holders,

Mountings, Edgings, Trim,

Retainers |

| Framing |

| Slats,

Strips, Gaskets, Battens |

| Panels,

Fins, Plates |

| Railings

& Brackets |

| Accompaniments |

| Misc.

Channels |

| |

|

|

|

|

|

|

|