About Us

Johnson Bros. beginning occurred when Edwin

Johnson, Sr. decided to go into business himself. In 1947, he

started constructing the company's first roll forming machine (now

in storage) in his basement. He had offered his five brothers and

equal share of the business if they matched his life savings, $700

investment. One brother, Harold Johnson, did; hence the name

Johnson Bros.

5500 Outside

When the first machine was finished and tested it had to be

disassembled, carried from his basement and reassembled in Edwin's

garage. After a few months the neighbors complained about the noise

as production of small orders began and Edwin was forced to find

new quarters. He found an uninsulated, dirt-floor garage that had

formerly been a stable at Cicero Ave. and Chicago Blvd. in Chicago.

The brothers, Edwin Sr. and Harold, insulated the garage/plant,

built a small office and heated the building with a small stove in

the cold months.

In 1950, Edwin Sr.'s son, Edwin Jr., who had been working part-time for the brothers since 1947 while going to college, and another brother of Edwin Sr. and Harold, not active in the

5500 Inside

In 1951, they rented a storefront on the garage property, built

two more roll form machines and grew the business. Besides

conducting all sales, Edwin Sr. designed all the dies (rolls and

cutoff) and the equipment (roll formers and flying cutoffs) in his

attic from 10 pm. (at

Low-stress day for our

shipping foreman

Two more brothers, Rudolf and Arnold, and a neighbor were hired

and the growing business was moved to Bellwood, IL, in 1954 to a

building formerly occupied by an old millwright. It was located

behind Borg-Warner,

4th generation works - Ed

Johnson Sr.'s great grandchildren

Rich Sandeen's

retirement

In 1963, Edwin Jr. designed (in the rough) a new plant (modular for expansion), which the architect of course finished. The building was completed and the company moved into its new plant in Berkeley, IL, in 1964. A 10,000 sq. ft. addition was completed in 1969, additional offices were built in 1978 and the business purchased its neighbor to the west's plant in 1998. Harold had retired in 1965 and Edwin Jr. became vice president/treasurer. Edwin Sr. stayed active until 1984 when illness at the age of 81 forced his retirement. After Edwin Sr.'s death in 1988, Edwin Jr. became president/treasurer/chairman of the roll forming, Chicago based company.

World's smallest roll

forming and slitter line

In 1978, Brad Johnson, Edwin Jr.'s son, had joined the business

working in the plant and learning the mechanical aspects very well.

Their purchasing agent's open heart surgery moved Brad into

purchasing. From there he moved into sales and in 1985, Brad became

vice president/sales manager. Today Brad is President & CEO. For seven years, Johnson Bros. was a three-generation

company.

World's smallest flying

cutoff press & runout table

The nature of Johnson Bros. roll forming has seen an evolution

from a lockseam and openseam tubing emphasis, which accelerated

their growth, to a diversity of shapes for many industrial uses and

now to sophisticated computer controlled in-line fabrication. Their

forming of

Personnel

Edwin Johnson, Sr.

The death of Edwin Johnson, Sr. on September 26, 1988, marked

the passing away of an American Pioneer in the traditional sense.

Johnson was President and Chairman of the Board at Johnson Bros.

Metal Forming Co. Born in Canada in 1903, growing up on the

farm,

Edwin Johnson, Sr.

Marian & Ed Johnson,

Jr., Rich Sandeen, Brad Johnson (President & CEO)

The Great Depression forced him back to his dad's farm on

northern Minnesota where he cut his own trees and built a log

cabin. One cow, hunting, fishing, gardening and odd jobs provided

for his young family.

In 1934, he returned to Chicago to work for Kroh-Wagner in

custom roll forming and in the mid-1940s for Maplewood Machinery in

roll form machine building. In 1947, he began building his first

roll forming machine in his basement and in 1948 he founded Johnson

Bros. Co. (later to be Johnson Bros. Metal Forming Co.) As

President he was actively engaged as chief engineer/tool

Ed Johnson, Jr. and MaryAnn's retirement

Johnson Bros. Metal Forming Co.'s service and expertise

continues. The addition of expert technical personnel during Mr.

Johnson's final years, together with the ongoing management team

allows Johnson Bros. to continue with the same competent and

conscientious service they have sought to provide since their

founding, but they sorely miss their pioneer, Edwin Johnson,

Sr.

For more information regarding the Johnson Brothers roll forming Chicago based company, Contact us!

Original founding Johnson

Bros. preparing headlight lens ring circa 1948

Johnson Bros. First Building on

Cicero Avenue.

|

Edwin Johnson, Sr., and Brother Arnie

preparing Roll Forming machine for sale at Cicero Avenue.

|

Harold Johnson performing Tool &

Die work at Cicero Avenue.

|

Ed Johnson, Sr., and Harold Johnson

preparing machine for sale at Cicero Avenue.

|

2nd Building in Bellwood, IL, owned

by Johnson Bros. Sign painted by Ed Johnson, Jr. Arnie Johnson and

his Olds.

|

|

Arnie Johnson on the fork lift at

Cicero Avenue.

|

Flying Cutoff Press Model. Designed,

built, and sold by Johnson Bros. 1957 Cicero Avenue.

|

Early Model Roll Former built at

Cicero Avenue location.

|

Rudy Johnson and Ed, Sr., at Cicero

Avenue with Ring Profiles Rolled & Bent.

|

Rudy Johnson and Ed, Sr., at Cicero

Avenue with Ring Profiles Rolled & Bent.

|

Ingwald Speed Johnson welding at

Bellwood facility.

|

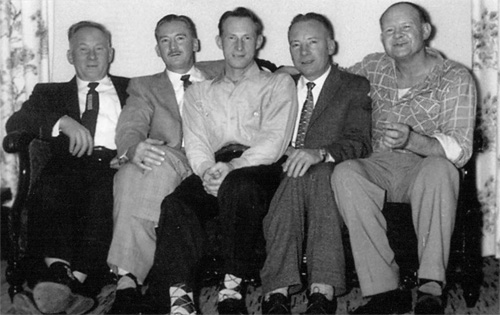

"The five original brothers employed at Johnson Bros. from left to right: Edwin Johnson, Sr., Rudy Johnson, Arnie Johnson, Harold Johnson, Oswald (Speed) Johnson"

We support many charities and nonprofits.

|